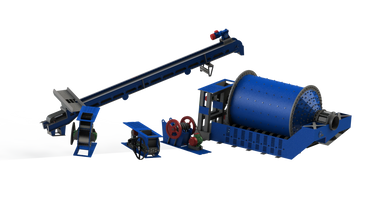

Go- STACK

GO-STACK

Jaw Crusher

GO-STACK

At Go-Mine, our mission is to provide safe and sustainable mining solutions that are innovative and cost-effective. We are committed to delivering exceptional value to our clients while maintaining the highest standards of safety and environmental responsibility.

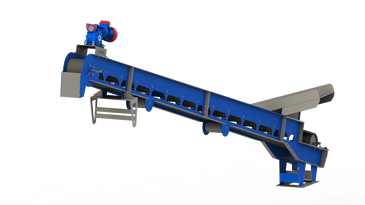

Conveyor

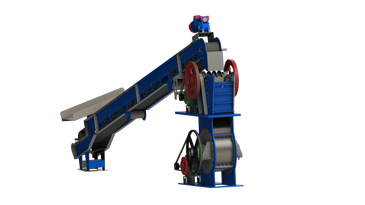

Jaw Crusher

GO-STACK

250mm wide x 6m long pre-fitted with a heed box, 1,5Kw motor and chain drive. it bolts apart into 5 sections for easy transport.

Jaw Crusher

Jaw Crusher

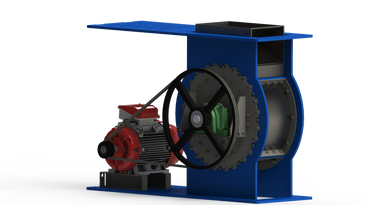

Double Roller Crusher

Build tough with a 5kw motor. Able to crush a maximum size of 125mm rock down the smallest setting of 20mm

Double Roller Crusher

Double Roller Crusher

Double Roller Crusher

This double roller crusher will reduce a rock of maximum 30mm to -5mm in size. by adding this unit in the line you will reduce you hammer mill wear and increase your ball mill throughput.

Hammer Mill

Double Roller Crusher

Hammer Mill

Fitted with a hardened steel router holding 32 specialized steel hammers rotating at 720 RPM shuttering the rock between the hammers and the impact liners of the mill to a point where they are fine enough to exit the mill trough the hardened laser-cut interchangeable screen.

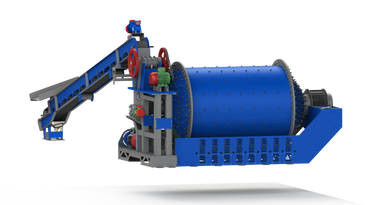

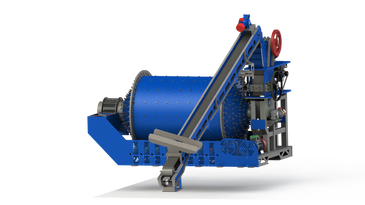

Ball mill

Double Roller Crusher

Hammer Mill

This is the more expensive option but it has less wear and tear than the hammer mill and if calculated over a 6 month period works out the cheaper option. pre-fitted with a screw feeder, vulcanized rubber with steel stiffeners and discharge screen.

Conveyor - Jaw - Hammer Mill

Conveyor - Jaw - Double Roller Crusher - Hammer Mill

Conveyor - Jaw - Hammer Mill

When processing sedimentary rock or quartz this is ideal budget friendly configuration.

Conveyor - Jaw - Ball Mill

Conveyor - Jaw - Double Roller Crusher - Hammer Mill

Conveyor - Jaw - Hammer Mill

When processing sedimentary rock or quartz this is ideal where the situation requires a higher throughput and a consistent find grind.

Conveyor - Jaw - Double Roller Crusher - Hammer Mill

Conveyor - Jaw - Double Roller Crusher - Hammer Mill

Conveyor - Jaw - Double Roller Crusher - Hammer Mill

This configuration is for areas with a thermal gold deposit where the rock is exceptionally hard and is the best way to conserve hammer wear by feeding the hammer mill with a smaller rock.

Conveyor - Jaw - Double Roller Crusher - Ball Mill

Conveyor - Jaw - Double Roller Crusher - Ball Mill

Conveyor - Jaw - Double Roller Crusher - Hammer Mill

This configuration is for areas with a thermal gold deposit where the rock is exceptionally hard and is the best way to increase the ball mill's throughput as you will be feeding a higher volume of smaller rock, reducing grind-time.

Hydro-Range

GO-HYDRO-FUGAL

The GO-HYDRO-FUGAL in short is a scavenging machine that exploits the difference in specific gravity of similar sized particles being pump through it. This is simply done by controlling the flow rate and the discharge rate allowing the centrifugal forces caused by the pump flow direction and specialised riffles will prevent material with a desired mass (SG) from flowing up and out. Making the GO-HYDRO-FUGAL the ideal product for continuous gold separation without the need to stop and flush.

Available in a 5, 10, 20, 30, 50, 100 and 200 Ton Per Hour unit

GO-HYDRO-SLUICE

Continuous self-cleaning sluice allowing for the heavy minerals to fall into a secure lock-box, thus increasing security and boost productivity as the user will not lose the hours of production per day it takes to clean-out a conventional sluice-box

Available in a 5, 10, 20, 30, 50, 100 and 200 Ton Per Hour unit

GO-HYDRO-WASH-PLANT

This wash plant makes use of the GO-HYDRO technology with conventional sluice mats acting as policeman. Designed to effectively recover coarse and fine gold in harsh clay or sandy deposits.

Available in a 5, 10, 20, 30, 50, 100 and 200 Ton Per Hou unit

GO-PRODUCT-RANGE

AUTO-BANKER

AUTO-BANKER

AUTO-BANKER

The Go-MINE-CC skid based wash plant with the following features:

Integrated spray bars with individual pressure control

Integrated eccentric beam with a veritable speed controller to increase or decrease deck vibration and speed

Detachable discharge conveyor

Dual sluices that can fold-in for easy transport

Feed pan

GO-LEGEND

AUTO-BANKER

AUTO-BANKER

Go-LEGEND is a horizontal continuous concentrator ideal to use as your first stage in a wash plant environment or a a concentrator in a crushing plant. The unit holds its trapped precious metals inside until you set it to clean-out mode by using a secure key.

RHT-5-GO

AUTO-BANKER

RHT-5-GO

The RHT-5-GO is a 5 ton per hour mobile wash plant that makes use of a internal scrubber that dumps it's washed and screened material on a helix spiral that pre-concentrates the gold before loading it onto a specialized sluice with a integrated nugget trap. The screened scrubbed material, waste of the spiral and tailing of the primary sl

The RHT-5-GO is a 5 ton per hour mobile wash plant that makes use of a internal scrubber that dumps it's washed and screened material on a helix spiral that pre-concentrates the gold before loading it onto a specialized sluice with a integrated nugget trap. The screened scrubbed material, waste of the spiral and tailing of the primary sluice is the washed into a final sluice to recover any gold that was missed and nuggets that could not fit through the screen.

GO-PRODUCT-RANGE

EL-WP-001

GO-MILLING-STATION

GO-MILLING-STATION

The EL-WP-001 artisanal alluvial gold wash plant is designed for the small scale miner to get his plant as close to the point of work as he can possible.

GO-MILLING-STATION

GO-MILLING-STATION

GO-MILLING-STATION

The 1 ton per hour gold stack is the ideal solution for a small scale gold miner or lab, the unit consist out of a Jaw crusher, Double roller mill and Hammer mill with 32 beaters.

If you are running small rocks you can use just the hammer mill, medium rocks you can add the double roller mill and for rocks bigger than 50mm you can use the

The 1 ton per hour gold stack is the ideal solution for a small scale gold miner or lab, the unit consist out of a Jaw crusher, Double roller mill and Hammer mill with 32 beaters.

If you are running small rocks you can use just the hammer mill, medium rocks you can add the double roller mill and for rocks bigger than 50mm you can use the complete stack. In softer rock conditions you can use the Jaw directly into the Hammer mill.

MGP-2-GO

GO-MILLING-STATION

MGP-2-GO

The monster MGP-2-GO is designed to process up to 3.5 tons of mineral ore per hour. This unit consist of a jaw, double roller mill, attrition mill and centrifugal concentrator

Build on a sturdy precision laser-cut frame with a specially designed stabilization jack system allowing you to rapidly deploy and work on ruff terrain.

About Go-Mine

MGP-1-GO

1 to 1,5 ton per hour mobile crush, mill and concentrate plant. Build to last in the tuff African mining industry.

.png/:/rs=h:104,cg:true,m/qt=q:95)